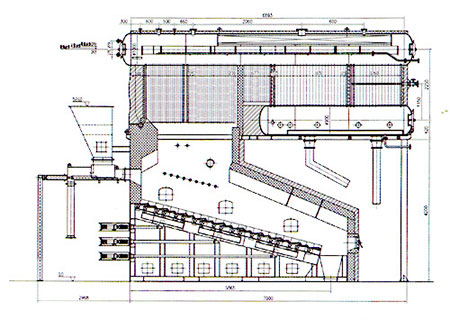

SZW series coconut shell boiler is a double-drum water-tube steam boiler. The boiler is divided into two parts: the upper body and the lower combustion equipment. The upper body of the boiler is composed of upper and lower drums, water-cooled walls connected to the left and right headers, and a convection tube bundle between the upper and lower drums. The inside is a furnace wall made of refractory bricks and refractory concrete and front and rear arches; the outside is a steel frame and Skin board, with insulation material in the middle. The boiler uses a large-angle inclined reciprocating grate, to meet the characteristics of light and fluffy residual ash after biomass combustion, so that it can be easily sent into the ash nest.

The biggest difference between the inclined reciprocating grate and the chain grate is that the fuel and the grate move relative to each other. The grate pieces are pushed backward and downward, and part of the new fuel is pushed to the upper part of the burned fuel, and the grate pieces are facing forward. On the return journey, a part of the burned fuel is brought to the bottom of the unburned fuel. Repeatedly, the conditions of the fuel in the fire preparation stage are improved. The front section, middle section and rear section of the air chamber are arranged at the bottom of the grate to achieve segmented air distribution.

Application

SZW series double drum steam boiler is widely used in industries, such as textile plant, rice mill, garment factory, utility for power plant, etc. The relevant capacity hot water boiler is widely used in hospital, hotel, school, farm, etc.

Technical Advantages

1. Compact structure, small floor space, single-story layout of the boiler room, and low capital investment.

2. High degree of assembly, short installation period and low installation cost.

3. The heating surface is fully and reasonably arranged, the boiler heats up quickly, the pressure rises quickly, the output is sufficient, and the thermal efficiency is high.

4. The grate is divided into air chambers for air intake, each air volume is independently adjustable, and the furnace discharge is steplessly adjusted to achieve full combustion.

5. The electric control cabinet is equipped with complete automatic control and detection instruments, with high degree of automation, safety and reliability, and easy operation.

Inquiry

Inquiry