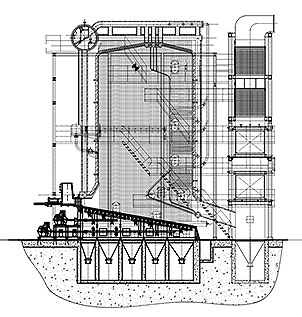

Corner tube boiler is the high-tech product with international advanced technologies, which use the technology of membrane water wall of power plant boiler to the industrial boiler, makes the boiler with better sealing performance and higher efficiency. Boiler water circulation system use the independent combination type of natural circulation and forced circulation, it has the characteristics of water circulation in safe and reliable. Since the boiler was supported by the 4 down comer, and has the function of water distribution, so it was called corner tube boiler.

Technical Advantages

1. large furnace with full membrane sealing structure, more suitable for the combustion of biomass boiler. Lower heat loss, higher thermal efficiency.

2. Larger water cooling degree reduce the risk of coking, more suitable for the larger capacity boilers.

3. Secondary air design make the air distribution more uniformly and better combustion performance, it also can reduce the generation of nitrogen oxides.

4. Independent furnace arch design, suitable for many kinds of biomass.

5. It adopts to the corrsgirder grate, less running resisitance, better cooling performance, lower breakdown rate, less fuel leakage.

Inquiry

Inquiry