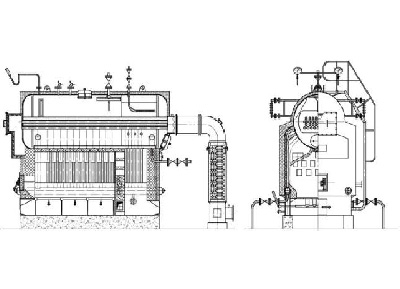

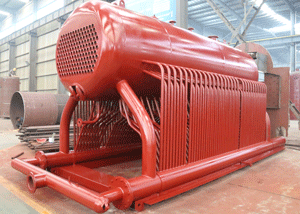

Wood fired moving grate boiler is single drum boiler with both water tube and fire tube, the combustion equipment is moving grate. Water wall tubes at left and right sides of furnace are the radiated heating area. the two wings at furnace and spirally corrugated tubes in the drum are convection heating area. This coal fired moving grate boiler uses the upper drum, water wall tube and head are in symmetrical arrangement mode. The furnace structure is in reasonable arrangement to achieve high efficiency.

Performance Advantages

1. Sufficient output

1) The wood boiler adopts horizontal type three pass structure and large furnace, could absorb the thermal expansion effectively.

2) The large diameter boiler drum increases the radiant heating surface, to ensure the sufficient output.

2. High thermal efficiency

1) The spirally corrugated tube strengthen the heat transfer, improve thermal efficiency.

2) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, increase thermal efficiency.

3. Avoid tube plate cracking

1) The boiler adopts arched tube plate and spirally corrugated tube, reduce stress, solves the problems of tube plate cracking.

2) Arrange two sides gas duct in drum, the smoke gas could enter into the front smoke chamber smoothly, the temperature of tube plate is lower than 600℃.

4. Environmental protection

1) The splayed wall and smoke outlet have the function of dust removal, decrease smoke emission.

2) The chain grate boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement.

Inquiry

Inquiry